From ideas to market: how our R&D brings value

We assist the customer from the early stages of the project through a careful analysis of the requirements. Together we define the technical requirements of the motor considering performance, dimensional and regulatory constraints.

Specific analysis

Joint evaluation with the customer of the required features, feasible solutions consistent with the desired cost targets, regulatory and product approval requirements.

Electrical sizing

By means of finite element calculations supplemented by preliminary experimental tests

Mechanical sizing

3D studies supported by structural calculations when necessary

Prototyping

Carried out largely in-house in our proto-shop

Testing and customer homologation

Dynamometer and customer application testing

Industrialisation

Manual, semi-automated or fully automated processes sized according to volume, product quality and cost target.

Operational steps

Designing

Prototyping

Testing

Industrialisation

Step 1

Designing

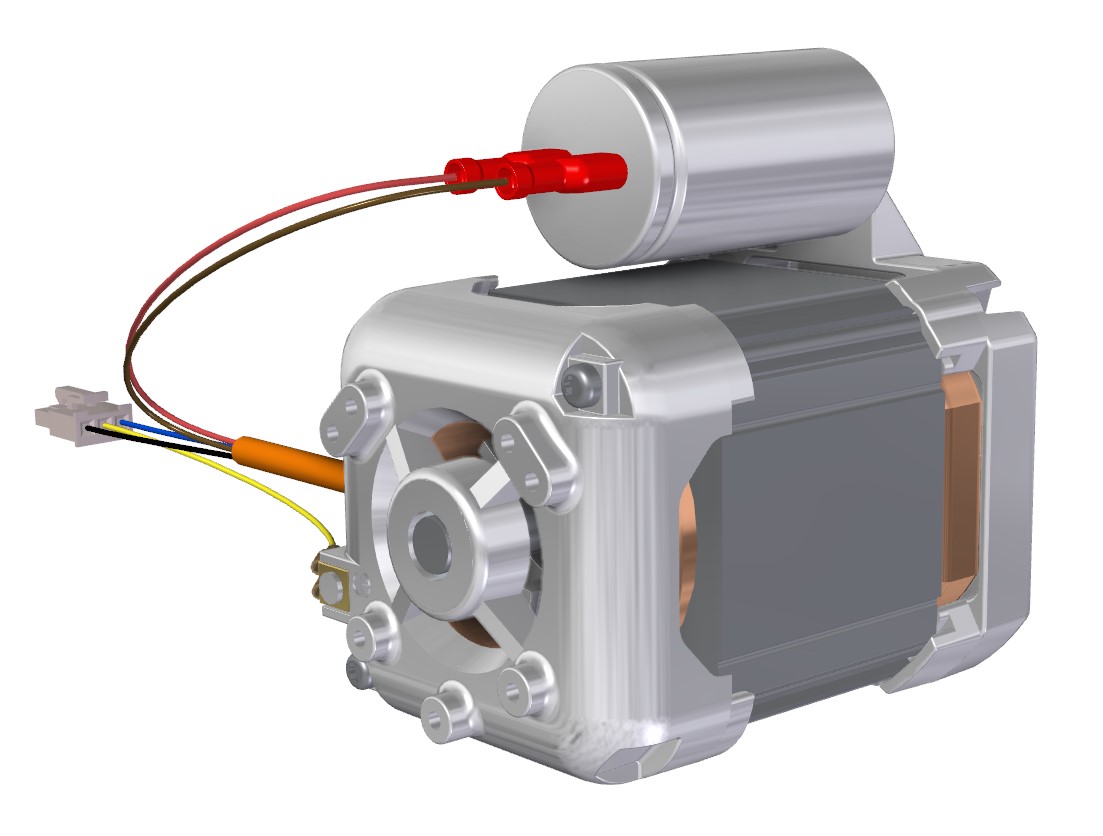

We develop custom projects from customer specifications, integrating our expertise in electrical engineering, mechanics and electronics.

We innovate existing products

We innovate by addressing design efforts to existing products, updating them in accordance with increasingly stringent regulatory requirements, proposing increasingly efficient and competitive sustainable solutions, and seeking possible applications in different markets with challenging technical requirements. With these projects, we aim to increase our competitiveness in the medium term.

R&D of new products

We also devote our energies to pure innovation projects, collaborating with research institutes and universities, with the aim of increasing our knowledge and proposing marketable products in the medium to long term.

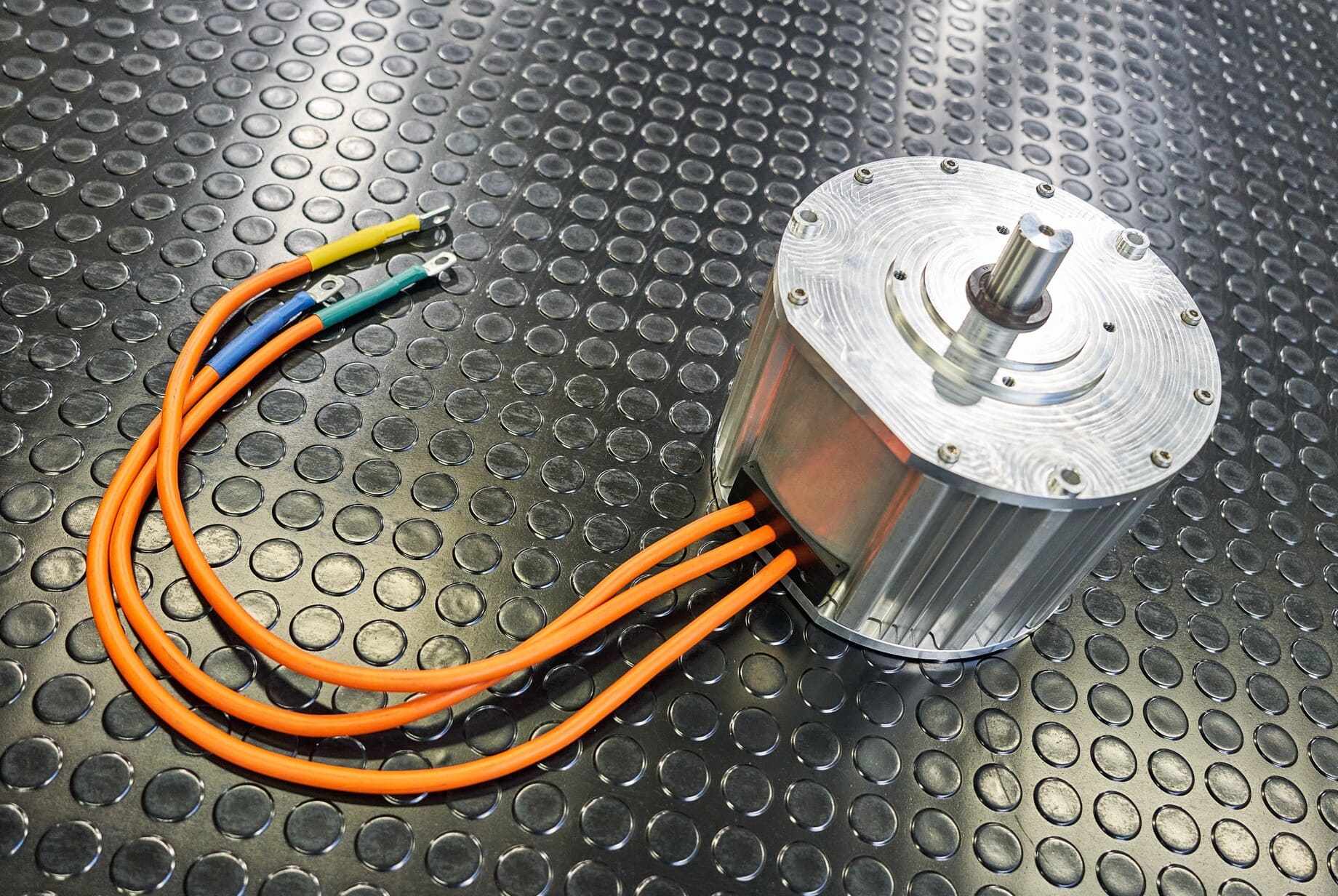

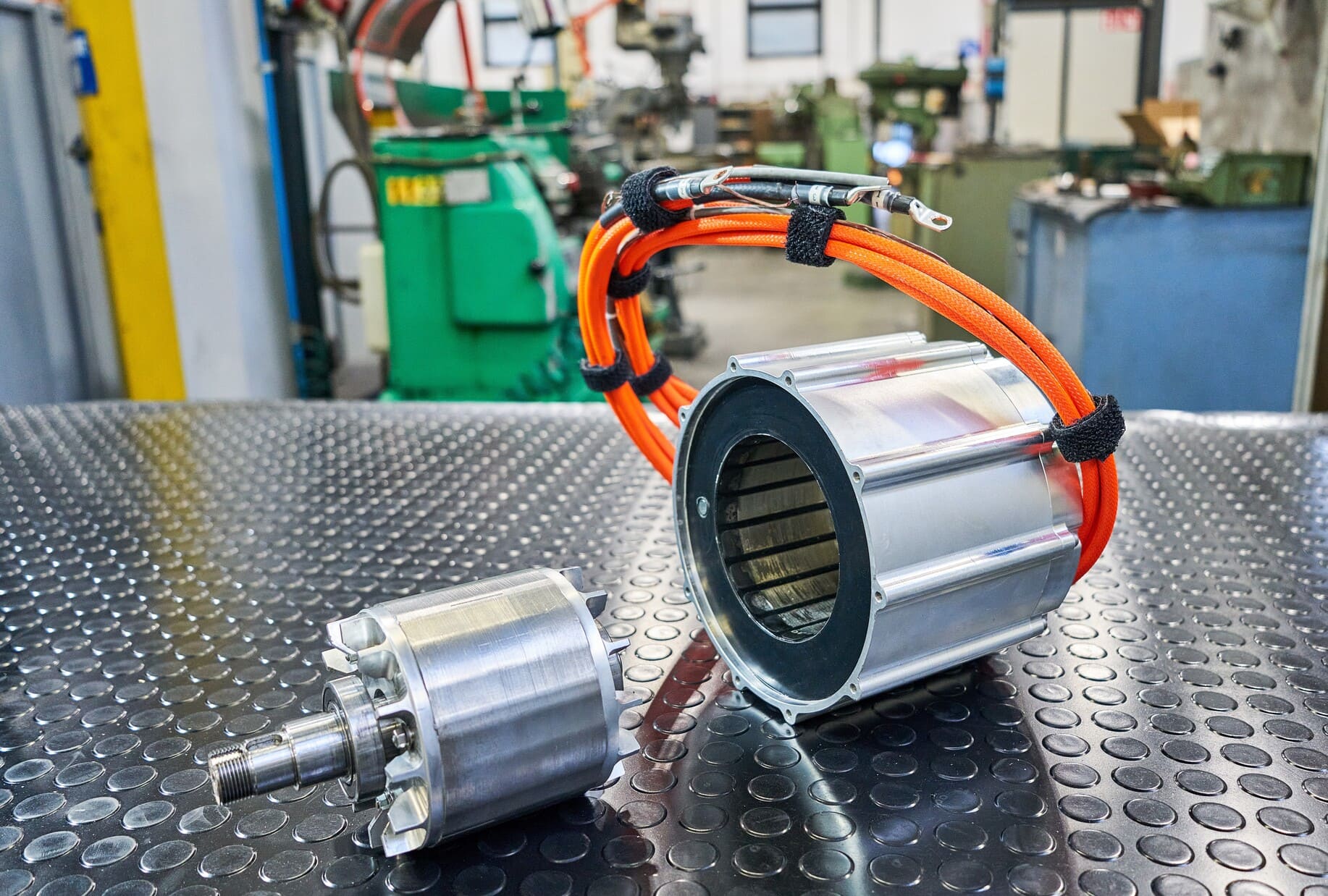

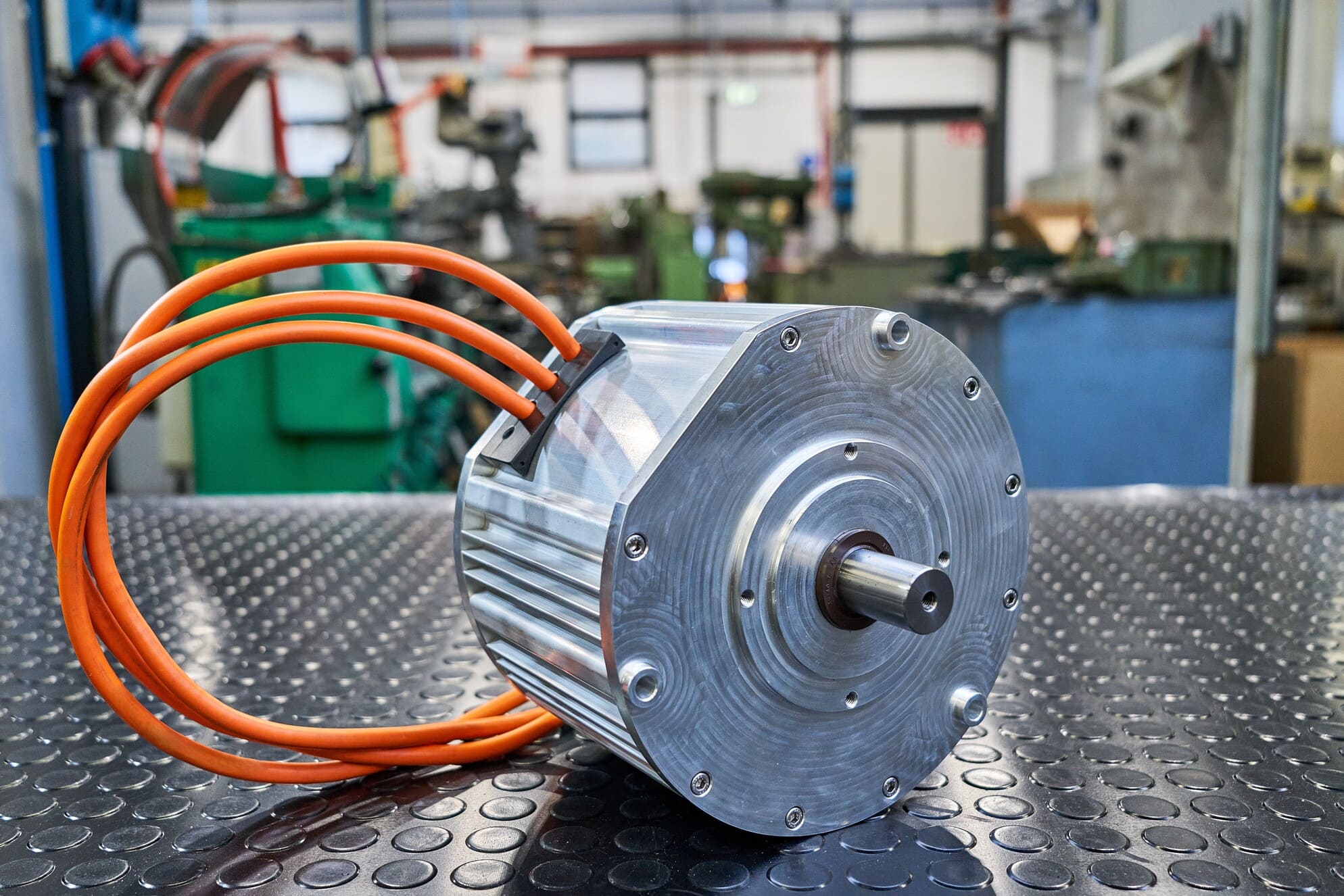

Step 2

Prototyping

Prototyping allows us to come into direct contact with our customers immediately, who can quickly verify that a new project meets their requirements.

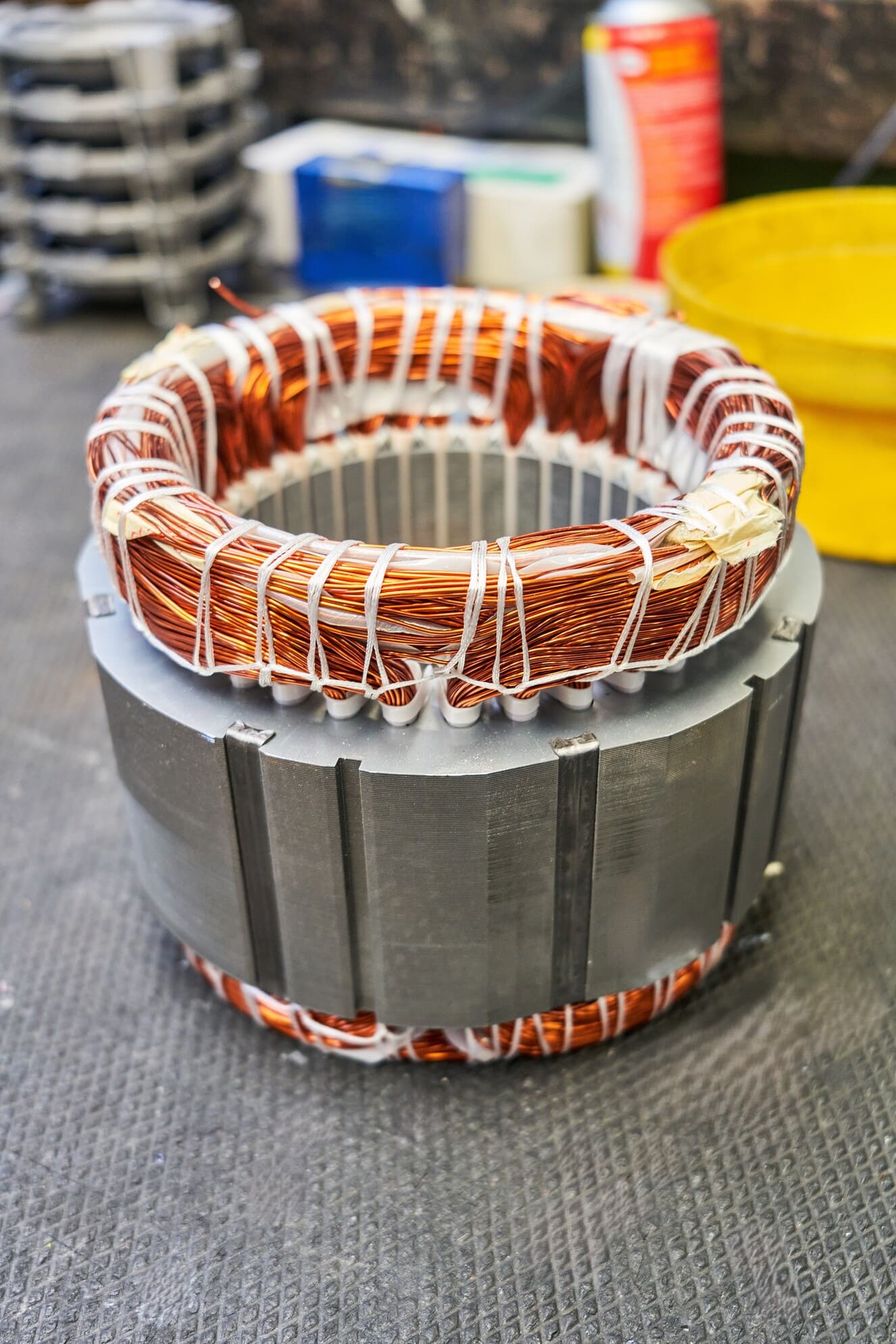

Concepts or components

We produce hundreds of prototypes per year. They can be first concepts or more industrialised components that will represent as much as possible the final product that we will realise in production.

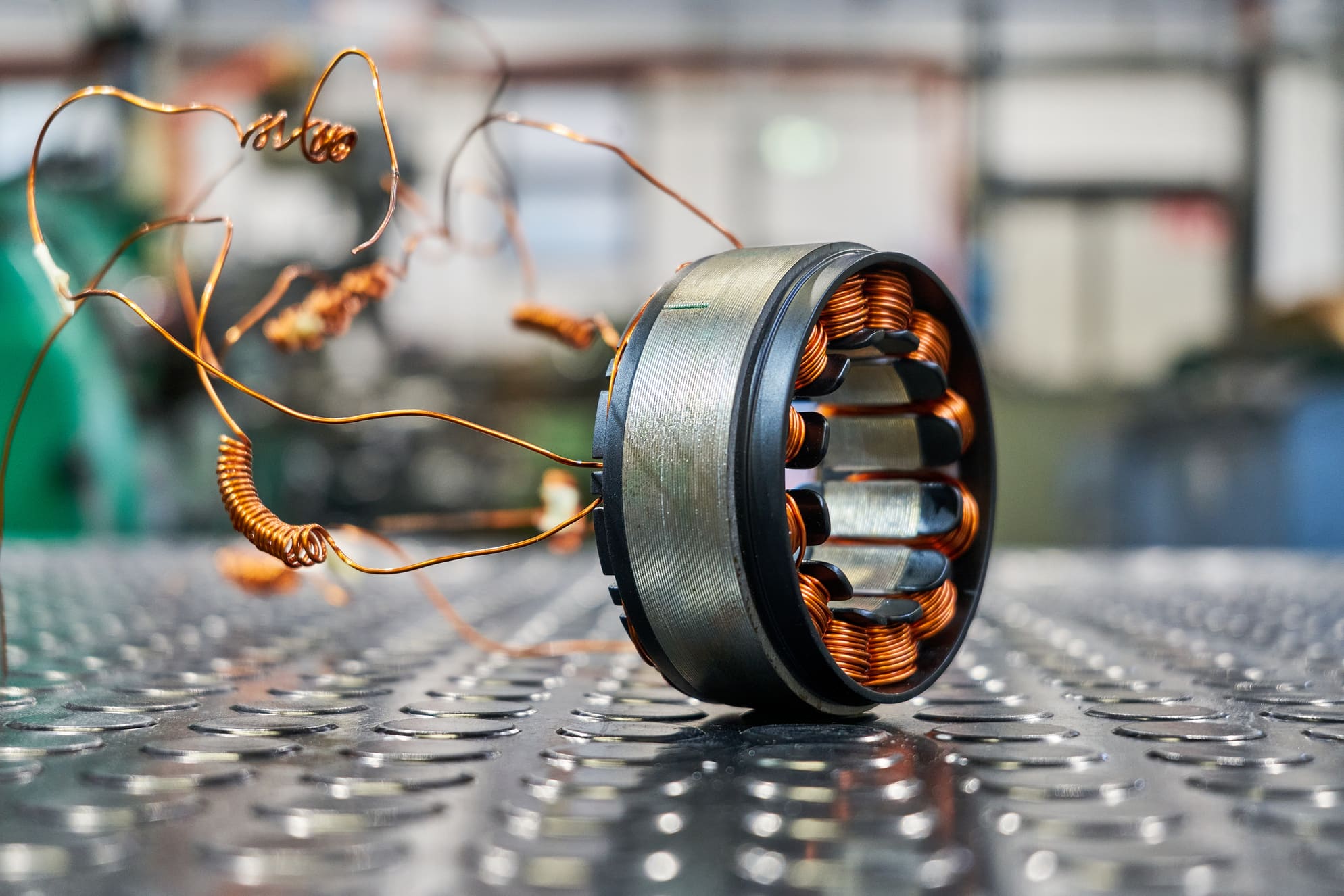

Dedicated centres

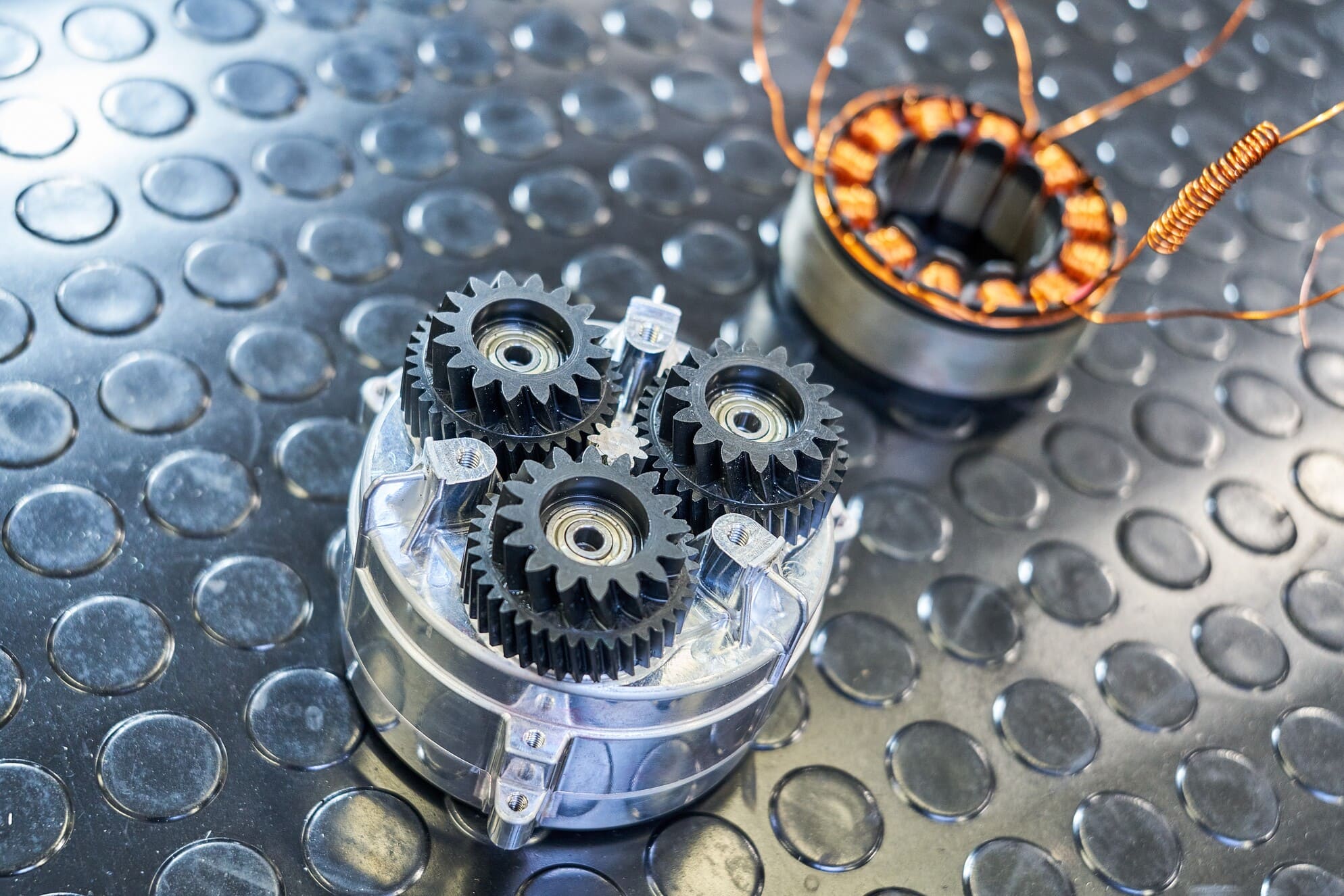

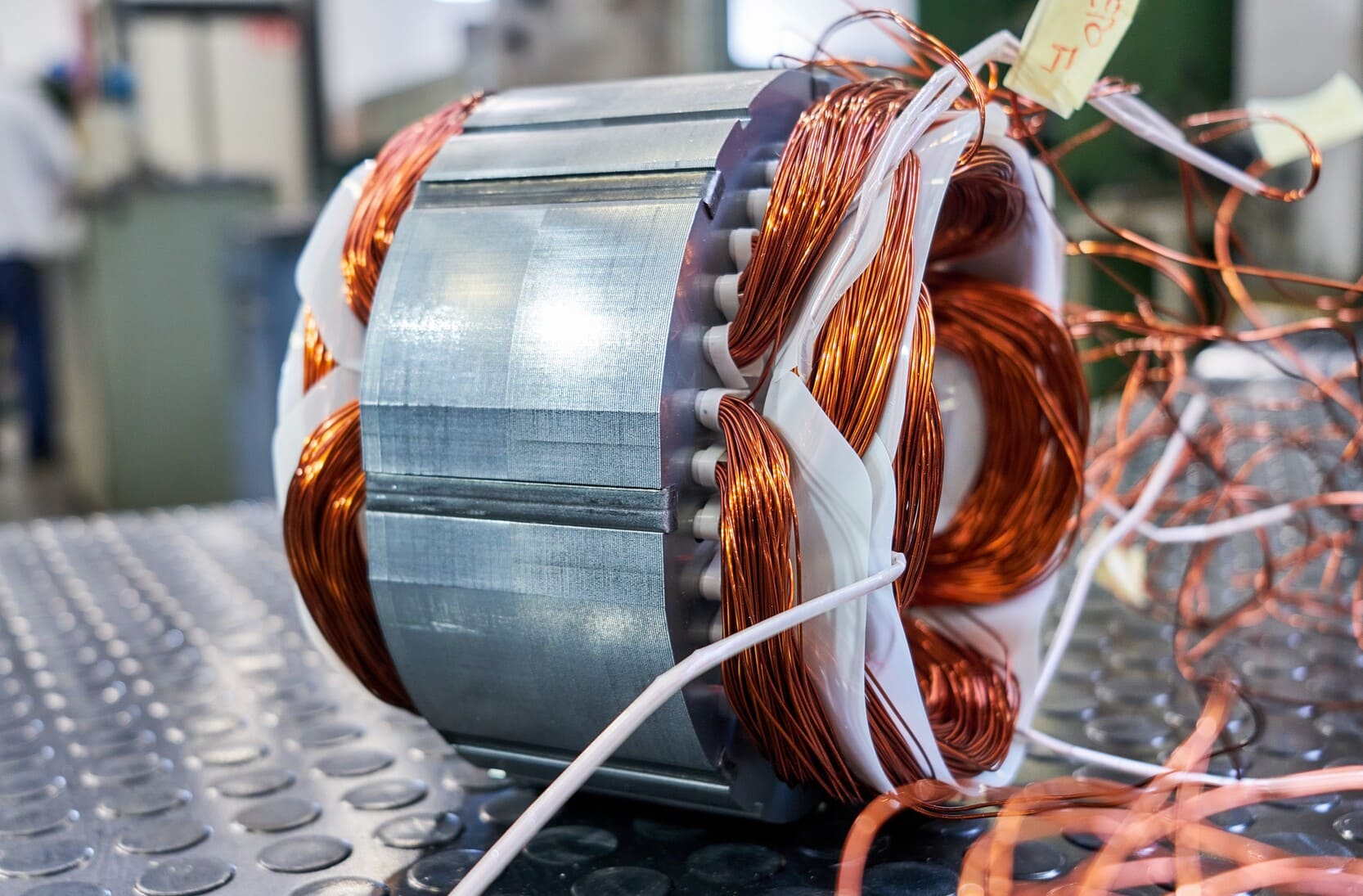

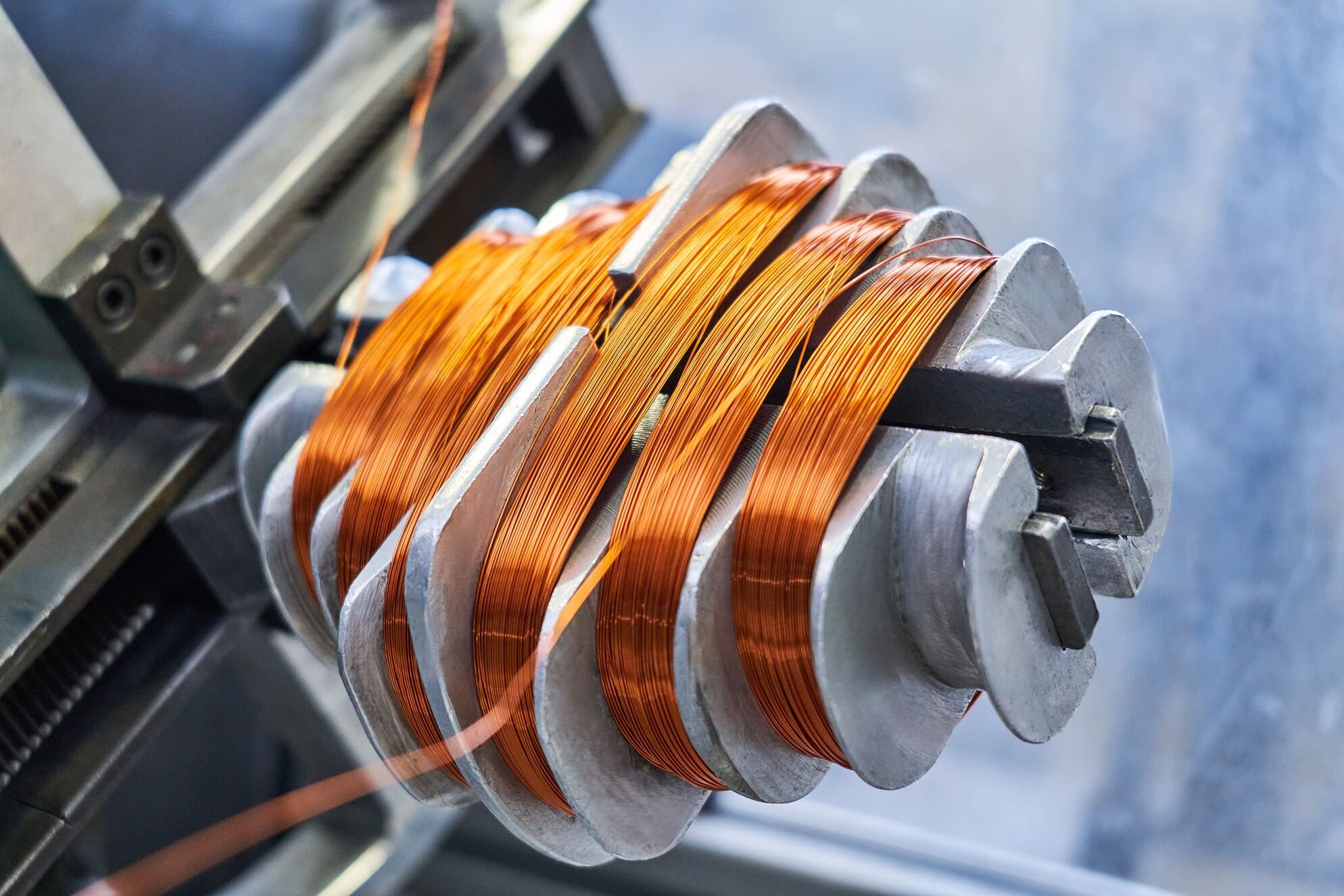

We machine almost all mechanical components on our machining centres, including balanced rotors dedicated to high-speed motors for specific applications. We are equipped with wire winding machines that produce concentrated or distributed windings.

Collaboration

We collaborate with external suppliers for sheet metal laser cutting and plastic moulding.

Step 3

Testing

Electromechanical performances

Electromechanical performance and thermal testing on dynamometers with 4 measuring ranges, torques from 1 Ncm to 50 Nm, powers from 200 mW to 40 kW

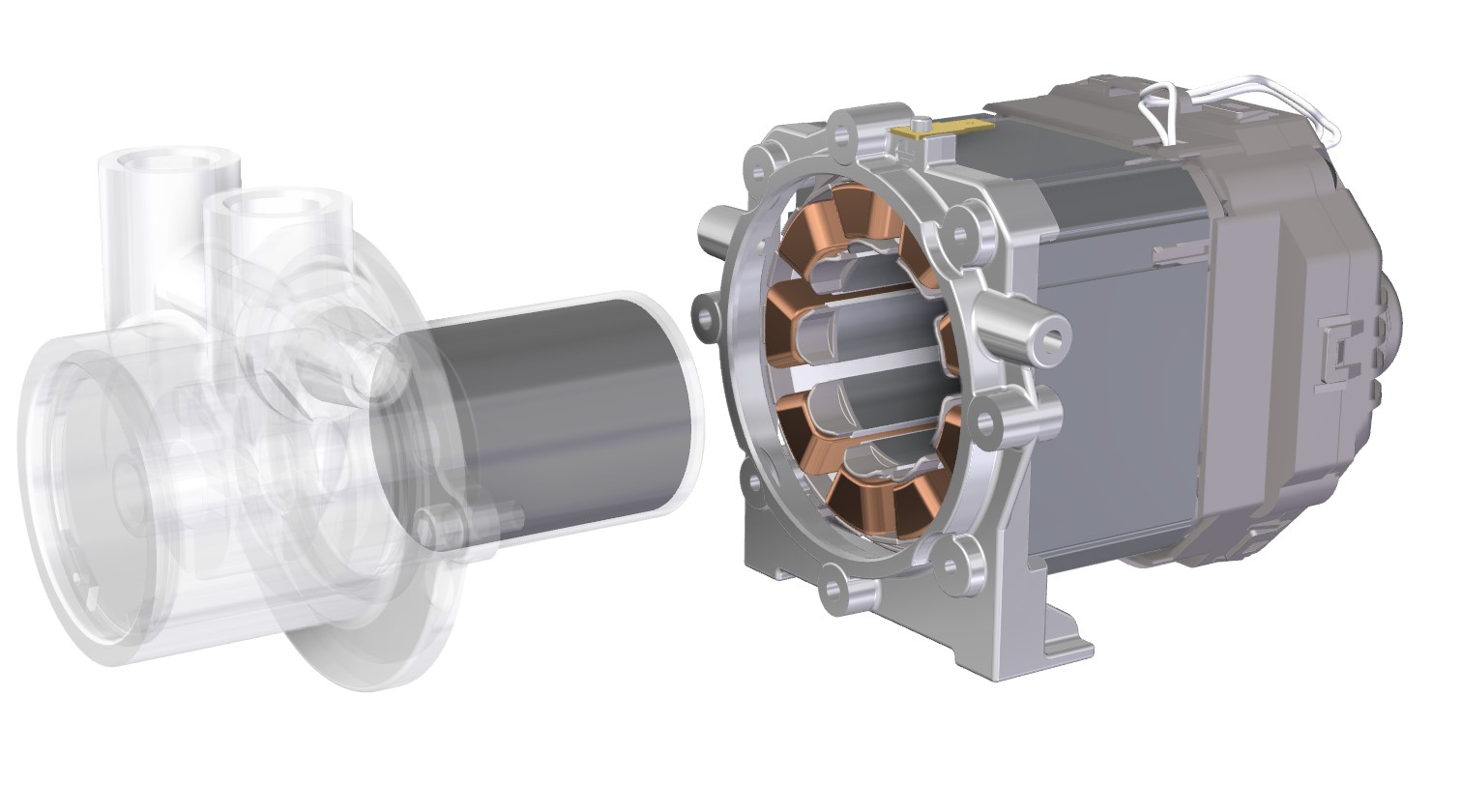

Performance on hydraulic bench

Performance on hydraulic bench with motors coupled to scrubber pumps (pressures up to 1000 mbar – flow rates up to 200 l/min) and rotary vane pumps (pressures up to 20 bar – flow rates up to 800 l/h), with determination of electrical, hydraulic and overall motor-pump efficiencies;

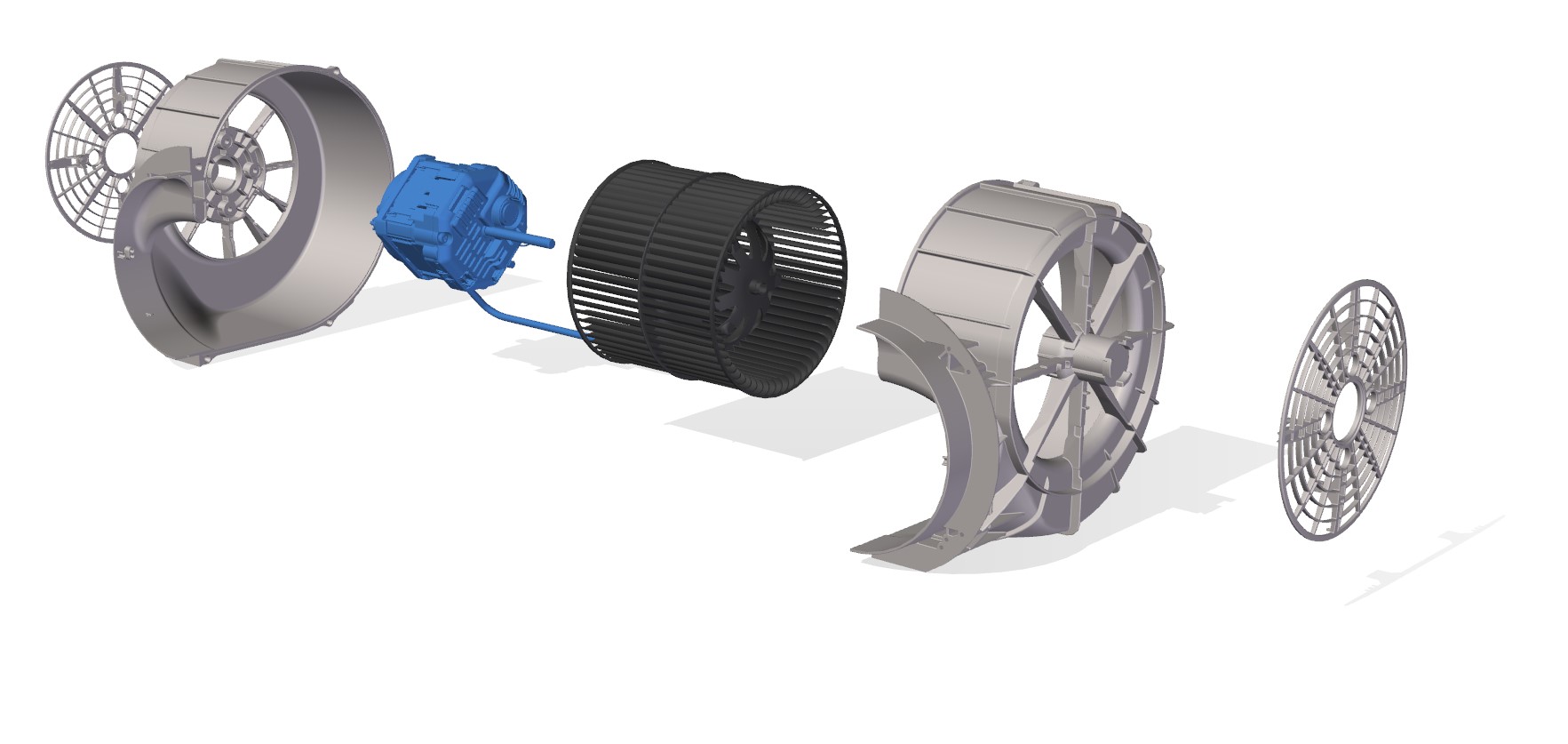

Performance on aeraulic bench

Performance on aeraulic bench with motors combined with centrifugal fans for fume hoods (pressures up to 1000 Pa – flow rates up to 1000 m3/h with determination of electrical, aeraulic and overall fan-motor efficiencies;

Thermal checks

Thermal checks on motors mounted in final appliance application;

Acoustic surveys

Thermal checks on motors mounted in final appliance application;

Electrical Security

Electrical Safety in accordance with IEC-EN 60034-1, IEC-EN 60335-1 and derivatives;

Conducted emissions measurements

EMC conducted emission measurements on motors and household appliances, in the presence of inverter drives

Reliability tests

Reliability and long life test;

Step 4

Industrialisation

From the earliest stages of the project, issues relating to the industrialisation of the product are evaluated. Depending on the volumes to be produced, the most suitable technical solutions and the degree of automation required are identified. This implies that we can move from manual or semi-automatic processes to produce small quantities, to processes where a high degree of automation is essential to achieve volume, quality and cost targets.